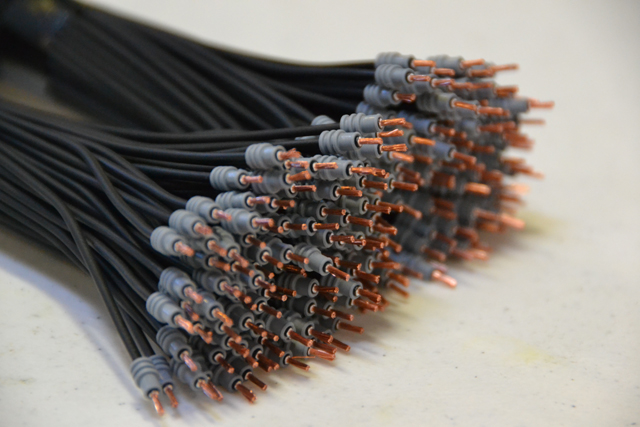

Custom Wire Harness Design and Production

From provided prints, to engineering services, Casper's does it all! Fast turn-around times and quality parts are our specialty!Any Quantity!

Casper's Electronics can handle any quantities! From prototypes, to low-runs, to production runs, we have you covered!Over 7000 Connectors IN STOCK!

With 0ver 7000 different connectors from both foreign and domestic manufacturers in stock, we can begin projects quickly!In-House Connector Design and Prototyping

Casper's Electronics has been designing mates to connectors not currently available in the marketplace for over 15 years! From concept to production part in approximately 30 days!TECHNOLOGY

Casper's Electronics maintains cutting edge equipment used to produce products! Better technology = better quality!Rapid Prototyping

Creating molds is only half the equation. How do you know if you are making a viable part? With in-house rapid prototyping, we can verify proof of concept immediately!

Casper’s Electronics, MADE IN THE USA

Quality Products & Services

Your one-stop-shop wire harness and connector manufacturer specializing in fast production dedicated to quality and service.

ISO 9001:2015 / ISO14001:2015 / ISO45001:2018

IMMEDIATE PRESS RELEASE – MAY 2024 Casper’s Electronics, Inc. is please to announce our successful completion of and audit of ISO 9001 and ISO 14001 and ISO 45001! CASPER’S will also pursue the latest revisions of the globally recognized standards. With constant improvement and evolution as a core part of our business model, CASPER’S continues […]

New Specifications

Casper’s Electronics – Loveland, COLORADO – 9/15/2014 We are please to announce the added capabilities of producing products that conform to the USCAR 21 and GMW3191 specifications. With a substantial investment into new equipment, we can easily produce harnesses, right here in the USA, that conform to these specifications if our customers require it.

25 years of experience and working closely with our customers has helped shape Casper’s into what it is today! We pride ourselves on customer service and quality products. Casper’s has achieved several certifications and there are several more in the works.

Some of the markets served include: Alternative Energy (CNG & LPG), High Performance Automotive, Heavy Trucking, Industrial, Agricultural, Military, Rail, and many, many others! Have a product you want to bring to market? We can help by lending our experience and expertise in design. Already have a product made? Let us help streamline it! We can offer suggestions and recommendations for product usage to save cost on raw materials and/or production times!

Read moreCasper’s Electronics has worked in almost every aspect of automotive wiring for over 25 years! Small and large quantity production of engine harnesses, adapters, custom product implementation, and custom made connectors are just a few of our specialties!

Our sales, engineering, and production support personnel are available any time to help you with your project! We have great control over production, so late stream engineering changes can be implemented quickly and efficiently.